Fault Detection System

Briggs & Stratton generators are equipped with sensors that automatically shut down the generator in the event of potentially damaging conditions, such as low oil pressure, high oil temperatures, over speed, etc. To your benefit, these generators have a control panel which will digitally display the fault codes. An LED indicator is installed at an inside location. The LED will turn on and off in a series of flashes if certain issues are detected. The blink pattern is repeated with a brief pause between each series. So, the fault code shown on the control panel and the number of blinks on the mounting plate will indicate the detected fault.

Low Battery Voltage (Code: FC_1)

Low Oil Pressure (Code: FC_2)

Low Voltage (Code: FC_3)

Engine Failing to Start (Code: FC_4)

Low Frequency (Code: FC_5)

Engine Overspeed (Code: FC_6)

High Oil Temperature (Code: FC_7)

Transfer Switch Fault (Code: FC_8)

Conclusion

There are a variety of error codes that you may see pop up on your Briggs & Stratton control panel. Although this may not be something you encounter often, you should still have an idea of how to resolve the issue. What’s more, is that the information found here could be utilized as preventative measures for you to take for your generator. You could solve the problem before any real damage is done. Hopefully, the information you’ve read here can help you navigate certain predicaments as they arise.

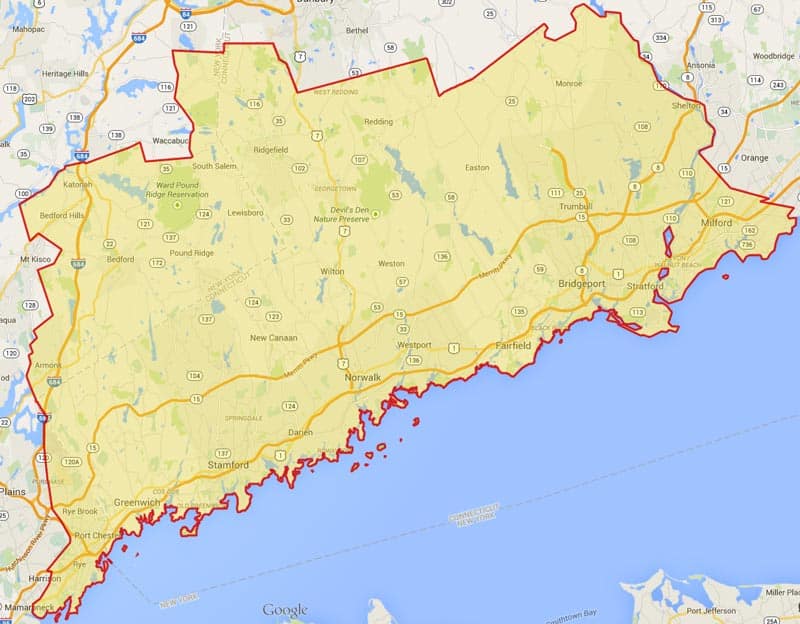

Contact Santella Electric, Fairfield County’s Generator Experts.

Recent Comments